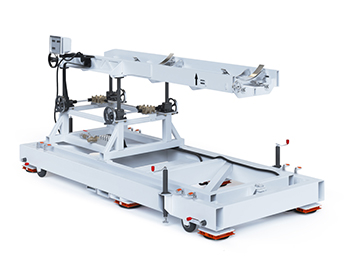

- Optimum flexibility for modular building transport: no first-in, first-out requirement

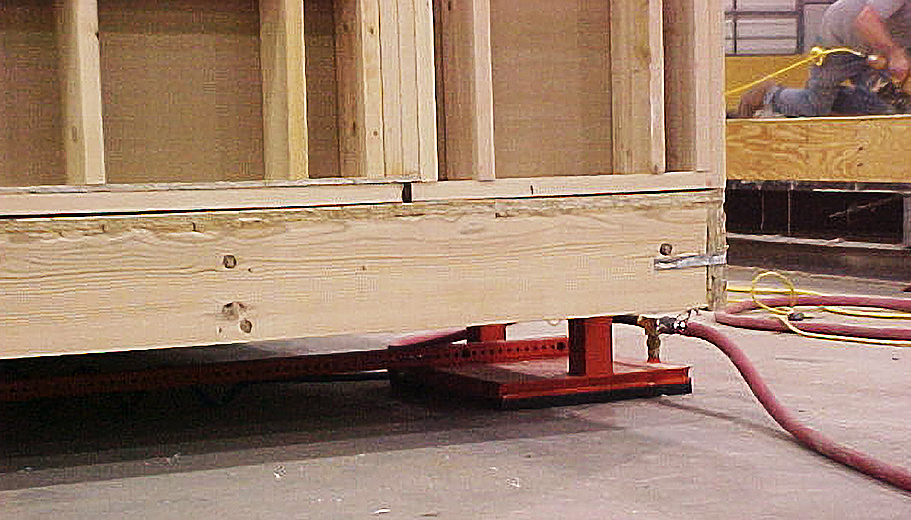

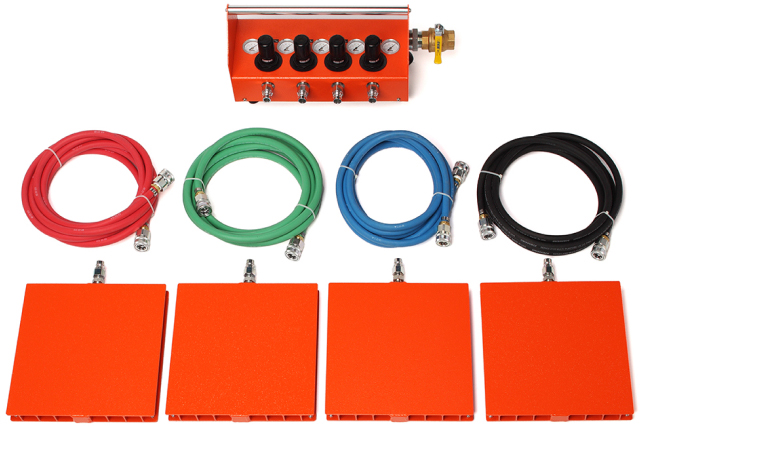

- Eliminate fixed paths, high step-ups or hard to move wheel systems

- Low friction: requires only 5-7 lbs. of force from the operator to move 1,000 lbs. of load

- Omnidirectional – move in any direction without increased force

- No moving parts means low maintenance, lower operating costs

- No in-floor hardware required

- CE compliant and ASME B30.1 compliant

The Problem Solver

Get the White Paper

Air Casters’ role in the Modular Construction Marketplace

What Our Customers Say

“I was very impressed. The system worked better than I could have asked for and everybody was astonished at how well they worked. 100% satisfied.”

“Quick response, on time delivery, support.”

“We manufacture very heavy products and large in size. Our first factory had a relatively thin cement slab and ceilings were made out of wood beams so overhead cranes and heavy load forklifts were not an option. So we decided to make our products fly!”

Proud Member Of