Consultative Problem-Solving: When Engineers Are in Charge of the Sales Process

When an organization has a tough material handling challenge, they don’t need salespeople. They need solutions.

Whether it’s NASA moving satellites, the Penn Museum of Archaeology moving a priceless sphinx, RISE Modular moving prebuilt homes, or any number of other applications, what they all share in common is a need to find the material handling system that will help them to be effective and efficient in their work. When they reach out to potential vendors, a pushy salesperson is the last thing that will help. Instead, they need engineering experts who can sit down with them, identify their foundational objectives and challenges, and then design or direct them toward a solution that will meet their needs.

That kind of consultative approach is how engineers handle sales.

Even if it means sometimes foregoing the sale.

“This kind of sales process makes the solution much more robust,” says Tom Gruber, Director of Engineering at AeroGo. “If somebody thinks what they need is a forklift, and that’s what they buy without due consideration, they’re stuck with the forklift regardless of what their actual needs are. They missed an opportunity to understand what could have genuinely solved their problem.”

In other words, treating the sales process as a solution-seeking opportunity means the customer is more likely to get what they need the first time, at the right cost, with no time wasted.

That’s why, for us at AeroGo, if a prospective customer comes to us and say, “I want an air vehicle to move this load,” our first response is to ask questions. The last thing we want is for our customers to end up with a solution that they never use. Maybe an air vehicle is genuinely the best option; it often is! But it could also be a forklift, a crane, or something else; and we have no way of knowing unless we dig into the situation collaboratively with the customer.

How Consultative Technical Problem-Solving Works

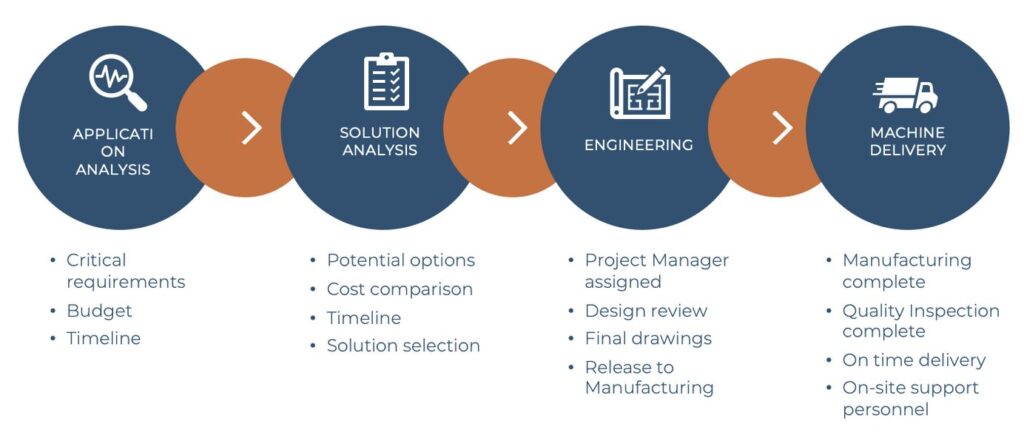

In general, a consultative approach means we go through a discovery process that may be more extensive than our customers expect.

- We explore the underlying problem to be solved, so we understand the core need.

- We ask quantitative questions, like measurements (“how heavy are the objects you need to move?”).

- We assess environmental conditions (“Can your existing floor surface support air casters? If not, would simple remediation tactics work?”).

- We consider any idiosyncratic elements unique to the application or situation.

Only then do we begin building or recommending a solution.

Here’s an example of the process at work: we had a research and development team from an online retailer approach us for help. They knew that precision movement would be paramount for their intended application, so air casters were a prime candidate for meeting their needs.

But air casters require facilities to meet certain conditions. Specifically, air caster performance can be impacted by floor design and quality. As we explored the situation further with them, they shared that they were still in early planning stages: “The new facility doesn’t even exist yet, and the floor isn’t even poured. We just need a plan ahead of time about how to move this.”

This gave us the opportunity to collaboratively design a solution around their facility and their facility around a solution to ensure optimum performance. We were able to help them define floor design, air compressor size and location, structural dimensions so that air casters would fit, and so on.

If they had purchased a solution off-the-shelf or, worse, purchased a poorly suited material handling system, they could well have ended up struggling to make the system work. As a result of the collaborative process, however, they got a solution that was a perfect fit for their needs and could ensure maximum performance and productivity.

Why It Works

As much as we want to make sales, we also want to avoid making a sale that goes to waste. By carefully defining the problem and refining a solution, everyone can feel confident they’ve got the right solution from the start. Just as importantly, we can make sure we identify any “unknown unknowns” – or risks or conditions that might prevent air casters from working. It’s easy to make assumptions about air casters and other material handling systems, and our own engineers are in the best position to unwind those assumptions and illuminate any blind spots.

At the end of the day, a consultative sales process is designed to deliver what the customer really wants: something that will just plain solve their problem.

Comments are closed.