- Lightweight modern aluminum construction for easy handling and insertion — up to 4 times lighter than competitive steel modules

- Superior lift height enables insertion moves and overcomes floor surface irregularities

- Highest operating pressure provides more lifting capacity in a smaller area

- Strongest construction/max lifespan – Aero-Casters exceed ASME B30.1, 2:1 overload requirements for air casters

- Flexible system moves variable loads from 500 lbs. to 270 tons

Rigging System Specifications

| Model | Capacity (lbs) | Air Flow++ (SCFM) | Control Console | Net Weight (lbs) |

|---|---|---|---|---|

| 4K8NL | 4000 | 32 | BN34 | 60 |

| 6K8NL | 6000 | 48 | BN66 | 105 |

| 4K12N-HLSML | 8000 | 48/108 | BN34 | 80 |

| 4K8NHDL | 8000 | 48 | BN34 | 60 |

| 4K12NL | 10000 | 56 | BN34 | 80 |

| 6K12N-HLSML | 12000 | 72/162 | BN66 | 135 |

| 6K8NHDL | 12000 | 72 | BN66 | 105 |

| 4K15N-HLSML | 14000 | 56/200 | BN64 | 115 |

| 6K12NL | 15000 | 84 | BN66 | 135 |

| 4K15NL | 17000 | 56 | BN64 | 115 |

| 4K12NHDL | 20000 | 64 | BN34 | 85 |

| 6K15N-HLSML | 21000 | 84/300 | BN66 | 170 |

| 6K15NL | 25500 | 84 | BN66 | 170 |

| 4K21NL | 28000 | 48 | BN64 | 170 |

| 4K21N-HLSML | 28000 | 64/240 | BN64 | 170 |

| 6K12NHDL | 30000 | 96 | BN66 | 140 |

| 4K15NHDL | 34000 | 80 | BN64 | 125 |

| 6K21NL | 42000 | 72 | BN66 | 255 |

| 6K21N-HLSML | 42000 | 96/360 | BN66 | 255 |

| 6K15NHDL | 51000 | 120 | BN66 | 185 |

| 4K27NL | 56000 | 88 | BN64 | 290 |

| 4K21NHDL | 64000 | 100 | BN64 | 185 |

| 6K27NL | 84000 | 132 | BN66 | 430 |

| 4K36NL | 96000 | 116 | BN64 | 460 |

| 6K21NHDL | 96000 | 150 | BN66 | 270 |

| 4K27NHDL | 112000 | 192 | BN84 | 315 |

| 6K36NL | 144000 | 174 | BN66 | 685 |

| 6K27NHDL | 168000 | 288 | BN86 | 460 |

| 4K48NL | 192000 | 124 | BN84 | 740 |

| 4K36NHDL | 200000 | 216 | BN84 | 480 |

| 6K48NL | 288000 | 186 | BN86 | 1100 |

| 6K36NHDL | 300000 | 324 | BN86 | 710 |

| 4K48NHDL | 360000 | 240 | BN84 | 820 |

| 6K48NHDL | 540000 | 360 | BN86 | 1220 |

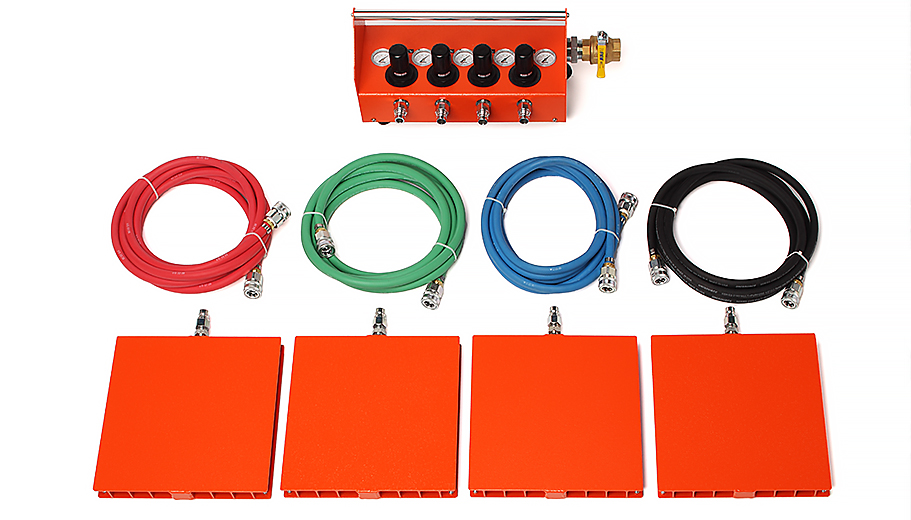

Each Load Module System includes:

Four or Six Load Modules with quick disconnect (QD) adapters

Four or Six 20′ long color coded interconnection hoses with quick disconnect (QD) coupler (both ends)

Four or Six station regulator control console with four or six quick disconnect (QD) adapter outlets and one on/off valve at the inlet.

++ NOTE ON ESTIMATED AIR FLOW – Air flow listed on this page is an estimate of the air flow at a given load, and a good operating surface. Always multiply this air flow data times 1.75 to provide a safety factor or when calculating air compressor requirements.

| Model | Capacity (kg) | Air Flow++ (L/sec) | Control Console | Net Weight (kg) |

|---|---|---|---|---|

| 4K8NL | 1816 | 15 | BN34 | 27 |

| 6K8NL | 2724 | 23 | BN66 | 48 |

| 4K12N-HLSML | 3628 | 22/52 | BN34 | 36 |

| 4K8NHDL | 3628 | 23 | BN34 | 27 |

| 4K12NL | 4536 | 26 | BN34 | 36 |

| 6K12N-HLSML | 5442 | 34/78 | BN66 | 61 |

| 6K8NHDL | 5442 | 34 | BN66 | 48 |

| 4K15N-HLSML | 6348 | 26/96 | BN64 | 52 |

| 6K12NL | 6804 | 40 | BN66 | 61 |

| 4K15NL | 7708 | 26 | BN64 | 52 |

| 4K12NHDL | 9072 | 30 | BN34 | 39 |

| 6K15N-HLSML | 9522 | 40/144 | BN66 | 77 |

| 6K15NL | 11562 | 40 | BN66 | 77 |

| 4K21NL | 12700 | 23 | BN64 | 77 |

| 4K21N-HLSML | 12700 | 30/112 | BN64 | 77 |

| 6K12NHDL | 13608 | 46 | BN66 | 64 |

| 4K15NHDL | 15420 | 38 | BN64 | 57 |

| 6K21NL | 19050 | 34 | BN66 | 116 |

| 6K21N-HLSML | 19050 | 46/168 | BN66 | 116 |

| 6K15NHDL | 23130 | 56 | BN66 | 84 |

| 4K27NL | 25396 | 42 | BN64 | 132 |

| 4K21NHDL | 29024 | 47 | BN64 | 84 |

| 6K27NL | 38094 | 62 | BN66 | 195 |

| 4K36NL | 43536 | 55 | BN64 | 209 |

| 6K21NHDL | 43536 | 71 | BN66 | 122 |

| 4K27NHDL | 50792 | 91 | BN84 | 143 |

| 6K36NL | 65304 | 82 | BN66 | 311 |

| 6K27NHDL | 76188 | 136 | BN86 | 209 |

| 4K48NL | 87076 | 58 | BN84 | 336 |

| 4K36NHDL | 90704 | 102 | BN84 | 218 |

| 6K48NL | 130614 | 88 | BN86 | 499 |

| 6K36NHDL | 136056 | 153 | BN86 | 322 |

| 4K48NHDL | 163264 | 113 | BN84 | 372 |

| 6K48NHDL | 244896 | 170 | BN86 | 553 |

Each Load Module System includes:

Four or Six Load Modules with quick disconnect (QD) adapters

Four or Six 6 meter long (20′) color coded interconnection hoses with quick disconnect (QD) coupler (both ends)

Four or Six station regulator control console with four or six quick disconnect (QD) adapter outlets and one on/off valve at the inlet.

++ NOTE ON ESTIMATED AIR FLOW – Air flow listed on this page is an estimate of the air flow at a given load, and a good operating surface. Always multiply this air flow data times 1.75 to provide a safety factor or when calculating air compressor requirements.

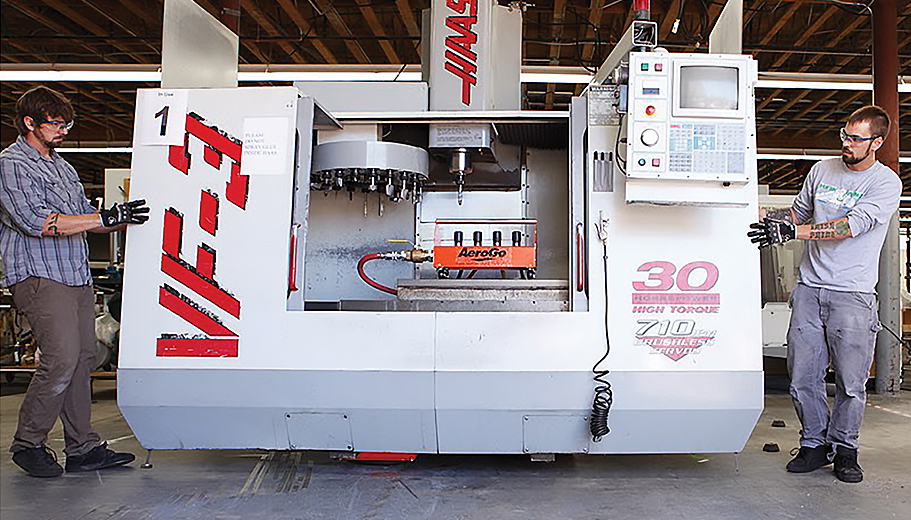

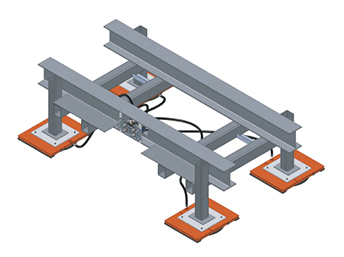

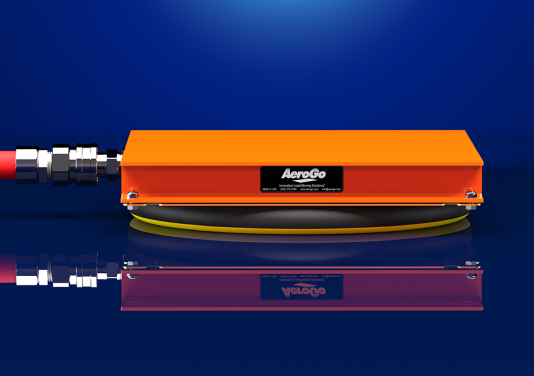

Product movement is already challenging, but things become increasingly complex when the process involves hefty items or exact positioning. Streamline equipment transportation and repositioning with an AeroGo Air Caster Rigging System, which supports and moves heavy loads using a thin layer of air.

The AeroGo Advantage

AeroGo is an ISO 9001 certified manufacturer of air caster rigging systems for industrial applications. Whether you’re assembling large piece parts into an assembly or relocating vital equipment, we have a movement solution to meet your needs.

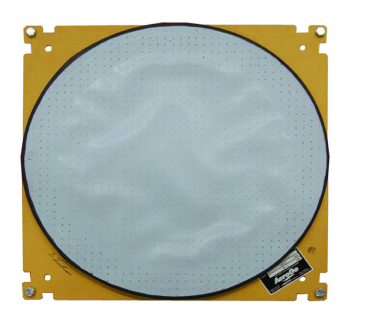

Air Caster Rigging Systems feature a modern aluminum construction – the lightest modules in the industry – making handling and insertion easy. They’re up to four times lighter than comparable steel modules but are capable of high operating pressures, providing more lifting capacity in a smaller area.

These flexible air bearing systems move variable loads from 500 pounds to 270 tons and are built to last. Heavy-duty handles safeguard the regulator, and AeroGo air casters exceed ASME B30.1, 2:1 overload specifications for air casters.

These air caster systems are perfect for any application, but typical uses include:

- Assembly Lines

- Plant Relocation

- Jacking or Rotating

- Production Line Rearrangement

- Large or Bulky Item Repair

- Heavy Machinery Movement

Frictionless Movement Technologies

At AeroGo, we understand no two applications are identical. That’s why our Air Caster Rigging Systems can be customized to meet your needs.

Special finishes are available for the Air Caster Rigging System. Control consoles that regulate air can be replaced and sold individually. For workspaces where gaps, cracks, or seams in the floor surface are present, a Gapmaster air caster system can be included. Storage cases, boxes, and carts can be provided to keep things secure and organized.

Industry Relies on AeroGo Air Caster Rigging Systems

Any industry where the safe, efficient movement of heavy or sizable items is common can benefit from AeroGo Air Caster Rigging Systems.

Let’s Work Together

In industrial settings, moving heavy machinery or loads is a necessity. An Air Caster Rigging System from AeroGo can move loads quickly, safely, and affordably while eliminating floor damage.

Contact us to learn more about our Air Caster Systems.

Rigging System Specifications (PDF)

Air Caster Rigging System Spec Sheet (English)Download

Air Caster Rigging System Spec Sheet (Español)Download

Air Caster Rigging System Spec Sheet (Deutsch)Download

Air Caster Rigging System Spec Sheet (Français)Download

Portable Rigging Kit Spec Sheet (English)Download

Air Caster Rigging Kit Spec Sheet (English)Download

How to Select the Best Load Movement System

A selection guide to evaluate 7 critical criteria

Get the guideWhat Our Customers Say

“We had to move a very large crate in a very tight area, where forklifts were hard to maneuver. We got bids on similar items but AeroGo had the best setup, price, and customer service. And it was in stock.”

DETROIT REMAN WEST

“We manufacture very heavy products and large in size. Our factory had a thin cement slab floor and ceilings made out of wood beams. Overhead cranes and heavy load forklifts were not an option. So we decided to move our products on air and make them fly!”

IO DATA

“We thoroughly enjoy working with AeroGo. Your engineers are smart, responsive, and creative. Of all the vendors I interface with, AeroGo is at the top of the list.”

“AeroGo is a solid company with knowledgeable folks. Very smooth process. Flexible to our needs.”

HEAVY EQUIPMENT MANUFACTURER

“AeroGo completed the order in shortest time, which was a special request from our side.”

AEROSPACE MANUFACTURER

““Recommended choice for replacement casters. Overall purchasing experience is good. AeroGo is fast with answers to questions.”

COMPRAS & SERVICIOS, QUERETARO, MEXICO

“We needed an alternate to forklift traffic. Needed something easier to move chopper heads. AeroGo’s got a good product.”

CNH, GRAND ISLAND, NE

“System worked far and above expectation. We had to move a 4,000 lb. aluminum chamber. The AeroGo lift system made easy work of moving it from the shipping and receiving dock to the work area through three sets of double doors and then another move to join the chamber with the rest of the tool. All done with only two people.”

INTEVAC, INC.

“For us AeroGo is a great supplier, with an excellent service and high quality products. We can achieve safety and improve the manufacturing development.”

TECMOLDIN INDUSTRIA DE MATRIZES

“Air bearings provide the low lift height and precise alignment we need without side guides. There was no way we could use conventional tracked crawlers or rails to move these casks.”

NUCLEAR PLANT MANAGER

“It was difficult to move cabinets by overhead crane in shorter time as set up time was higher. Therefore, to improve the movement time we decided to use AeroGo Air Caster.”

SIEMENS LTD., INDIA

“We chose air casters when other options were exhausted. AeroGo complied most with our changing requirements and within a relatively short response time. The Application Engineer was accommodating of all the requests, changes, & quick response nature of our company. High marks on engineering support.”

AEROSPACE COMPANY

“AeroGo brings much more to the table than products. They bring one vital component missing from many other manufacturer’s “products”…that is, AeroGo offers the ability to engineer products customized for our client’s needs.”

MUSTANG ENGINEERING

“AeroGo air casters were chosen to fix our load moving problem because they were the most suitable solution. The timely and professional service was a positive experience on this project.”

SIEMENS JINAN, SHANDONG PROVINCE

“We can’t use forklifts or anything that could damage the floors. Amazon was blown away by how easy it was.”

RIGGER, HAUPPAUGE NY

“Responsiveness and engineering support are excellent. Very satisfied with the specific product features, brand reputation and warranty.”

BENASSI SRL, ITALY

“I was very impressed. The system worked better than I could have asked for and everybody was astonished at how well it worked. 100% satisfied.”

T&D MACHINE

“Moving a building used to take two men eight hours, now takes two men 30 minutes, and it is achieved with a higher level of safety than before. Everyone at Ergon is so impressed, I was submitted for an Innovation Award for introducing the idea.”

ERGON ENERGY

“Air casters provided a better long-term cost solution than disassembling/reassembling our structure.”

BALL AEROSPACE

“Needed a method to move a table on a machine easily with one person. Wheels required too many people. Took a chance on AeroGo and it worked far better than expected. Helpful people who know their product.”

TAYLOR METAL SERVICES

“AeroGo air casters have been a part of the process for years. We have a good, established relationship. Pricing and service is well established. AeroGo’s knowledge of equipment made the transaction smoother.”

EVERGREEN PACKAGING

“I typically do not fill out surveys but have always been impressed with AeroGo products. The crew is very satisfied with the performance and ease of use and ability to synchronize the 4 casters. I will continue to recommend your product line to others.”

RIGGERS & HEAVY HAULERS

“We chose air casters as the solution to our load moving problem because the system is so flexible.”

NATIONAL TRANSFORMER TEST CENTER, SHENYANG

“Very happy with the product. I bought a set from you about a year ago. I don't know what I would do without them. We have been moving precast concrete hot tubs around.”